Make Better Parts With Synventive

AutomotiveEvery market has unique application requirements, but one truth remains consistent: molders need a hot runner system to produce consistent parts, efficiently, and reliably. Synventive custom engineers and manufacturers reliable hot runner systems for each part’s specific application needs.

Synventive provides the Electronics market with high-quality systems that deliver performance for very demanding applications.

Learn MoreSynventive offers solutions and experience to the Industrial market that provide exceptional performance and quality.

Learn MoreThe molding world is changing quickly and Synventive is ready to help you evolve with it.

Learn MoreSynventive provides systems to the Medical market that are engineered for both performance and high quality.

Learn Moretest title

Synventive provides the Electronics market with high-quality systems that deliver performance for very demanding applications.

Learn MoreSynventive provides the Packaging market with hot runner systems that meet the challenges these types of parts provide.

Learn MoreSynventive offers solutions and experience to the Industrial market that provide exceptional performance and quality.

Learn MoreThe molding world is changing quickly and Synventive is ready to help you evolve with it.

Learn MoreSynventive provides systems to the Medical market that are engineered for both performance and high quality.

Learn MoreTailored Hot Runner Solutions

Achieve perfectly balanced parts for interior and exterior applications.

Achieve perfectly balanced parts for interior and exterior applications.

Solutions for powerful components and challenging materials.

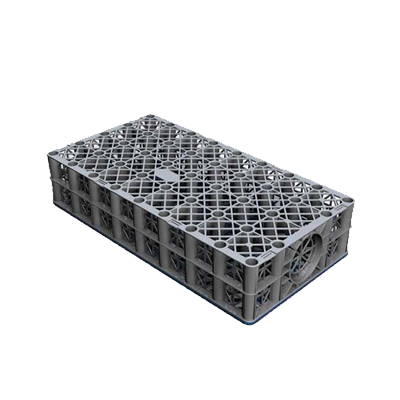

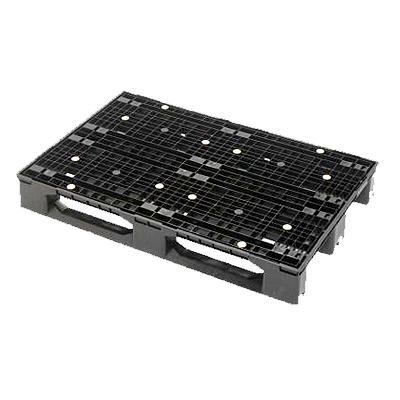

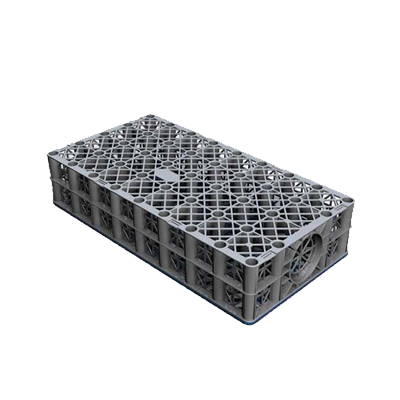

All you need in Industry and Logistics.

Make your home more comfortable.

Solutions for Future Generations.

Make Better Parts With Synventive.

Every market has unique application requirements, but one truth remains consistent: molders need a hot runner system to produce consistent parts- efficiently and reliably. Synventive manufactures reliable hot runner systems for each part’s specific application needs.

Industrial and Consumer Electronics & Electrics, Power Tools, Domestic Appliances

Learn MoreGlobal Leader in Automotive Parts

Global Leader in Automotive Parts

Synventive is the leading hot runner supplier to the global automotive industry, with a deep understanding of the rapidly changing automotive market, and is a proven partner in helping our customers find success in today’s EV revolution.

One of the most challenging and demanding markets in plastics, the automotive market requires not only Just-in-Time production requirements and a high degree of customer service, but also technological advances that drive innovation in injection-molded plastics on a continual basis.

Global Leader in Automotive Parts

Synventive is the leading hot runner supplier to the global automotive industry, with a deep understanding of the rapidly changing automotive market, and is a proven partner in helping our customers find success in today’s EV revolution.

One of the most challenging and demanding markets in plastics, the automotive market requires not only Just-in-Time production requirements and a high degree of customer service but also technological advances that drive innovation in injection-molded plastics on a continual basis. This high degree of expected service and inventiveness is the very nature of Synventive, and it’s what has led the company to its leadership position in this market.

Synventive has the deep knowledge base and easy-to-use technology to manage all the molding challenges in the automotive market, including high-pressure molding, balanced fill, color change, family molds, critical dimensions, A+ cosmetic surfaces, multicolor molding, and in-mold labeling.

- Interior

- Exterior

- Lightweighting

- Engine

- Lighting

- Heavy Truck

Interior

Great Automotive Parts, Inside and Out

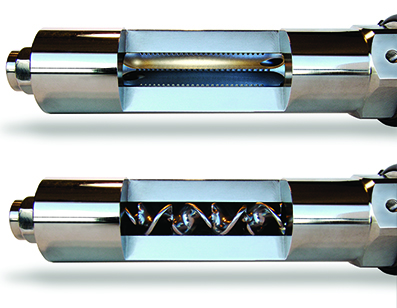

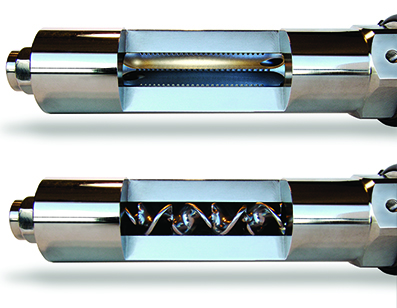

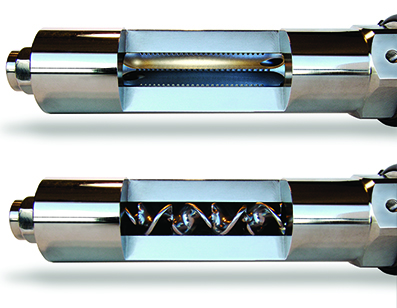

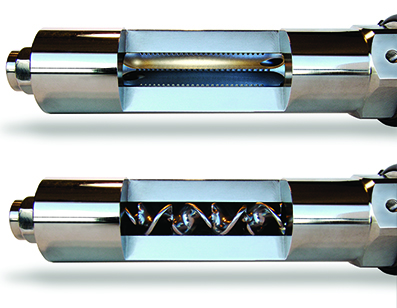

Nozzles

Nozzles

Nozzles

Nozzles

Exterior

Perfect Cosmetic Quality for Exterior Applications

Rear Lamp

Headlamp

Rear Lamp

Rear Lamp

Rear Lamp

Lightweighting

Bring Your Long-Range EV Goals to Life

Nozzles

Nozzles

Nozzles

Nozzles

Engine

Mold Robust Under Hood Parts Quickly

Rear Lamp

Headlamp

Rear Lamp

Rear Lamp

Rear Lamp

Lighting

Beautiful Lighting Solutions for High-Quality Parts

Rear Lamp

Headlamp

Rear Lamp

Rear Lamp

Rear Lamp

Heavy Truck

Easily Mold Large Parts With Robust Materials

Rear Lamp

Headlamp

Rear Lamp

Rear Lamp

Rear Lamp

- Interior

- Exterior

- Under-Hood

- Lighting

- Auto Electrics

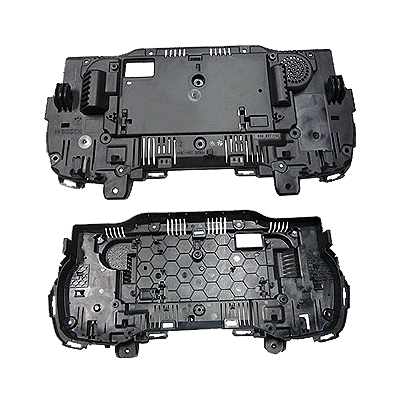

Great Automotive Parts, Inside and Out

Speaker Cover

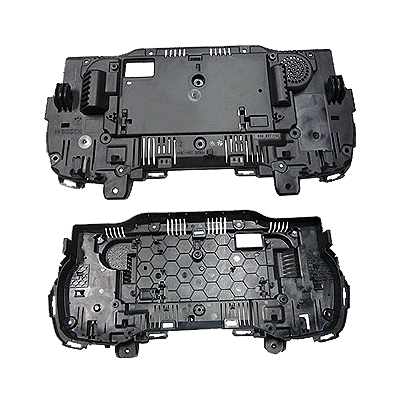

Instrument Panel

Cockpit Carrier

Control Panel

Horn Ring

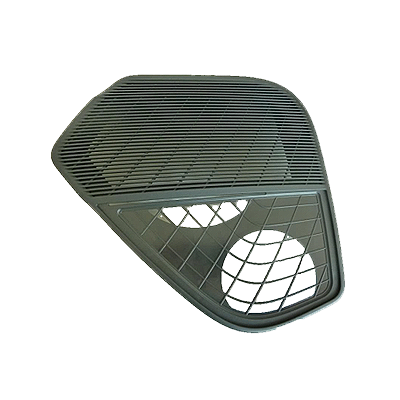

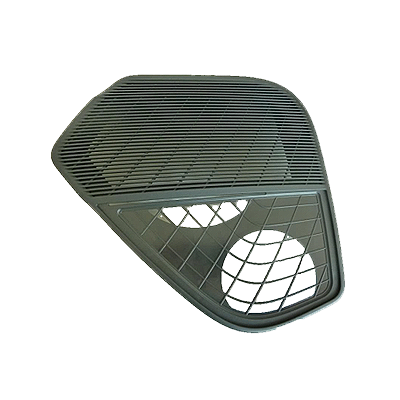

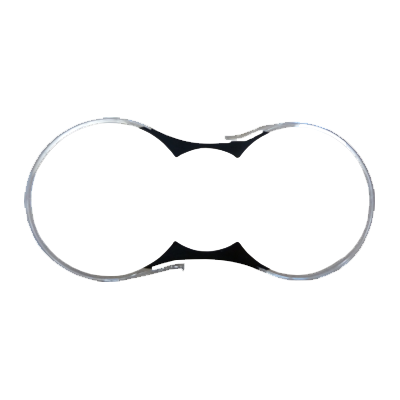

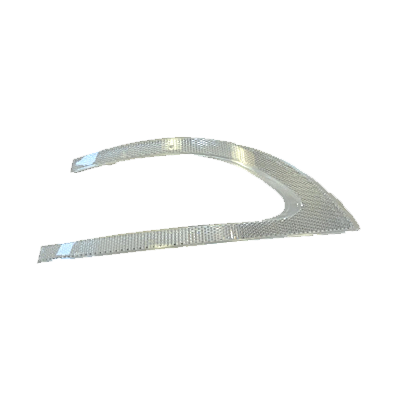

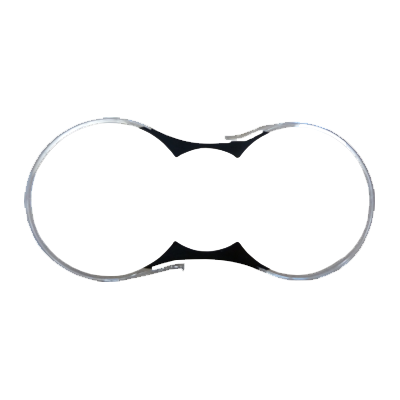

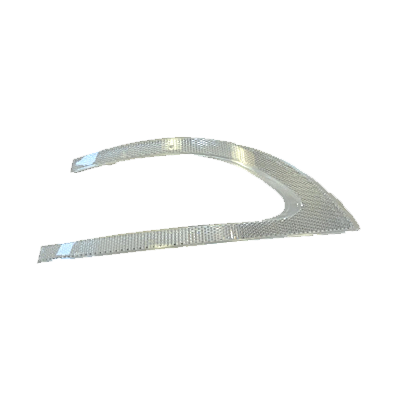

Perfect Cosmetic Quality for Exterior Applications

Bumper

Deco Trim

Pillar Cover

Wheel Spoiler

Radiator Grill

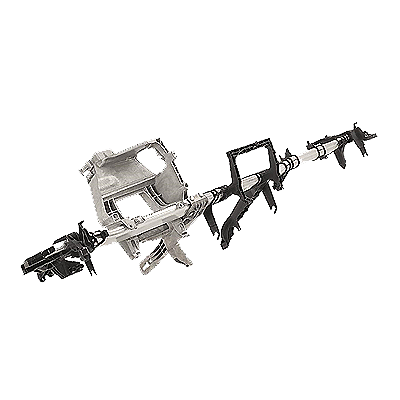

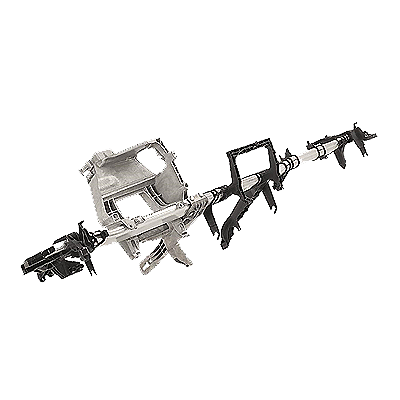

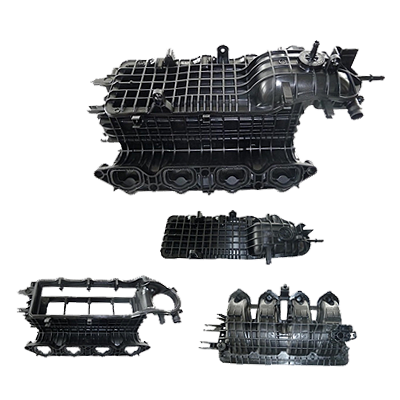

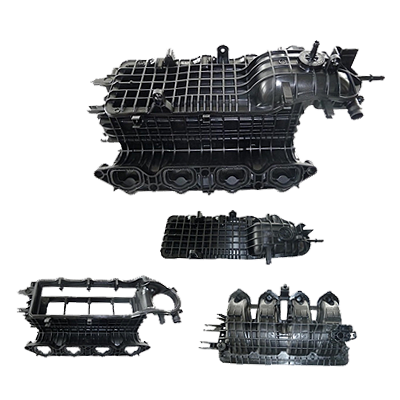

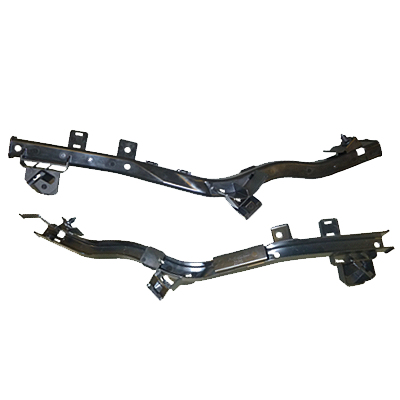

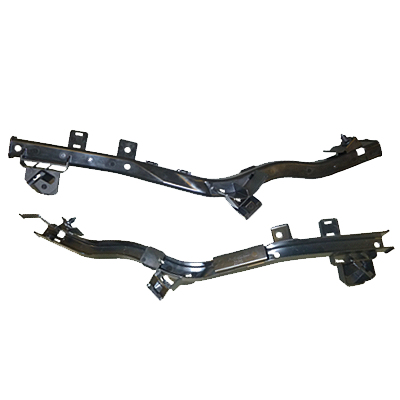

Mold Robust Under-Hood Parts Quickly

Oil Sump

Intake Manifold

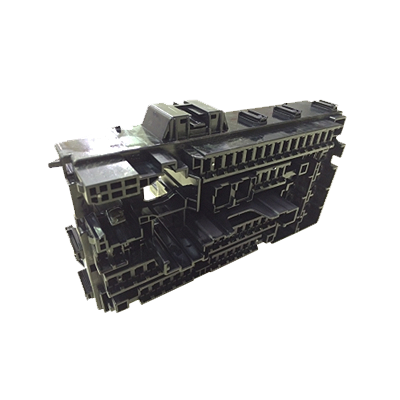

Fuse Box

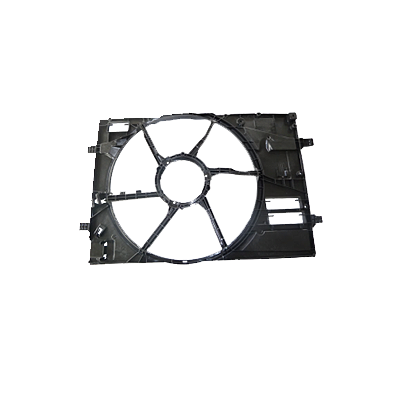

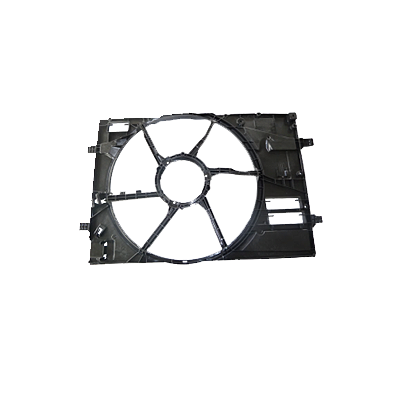

Fan Shroud

Engine Cover

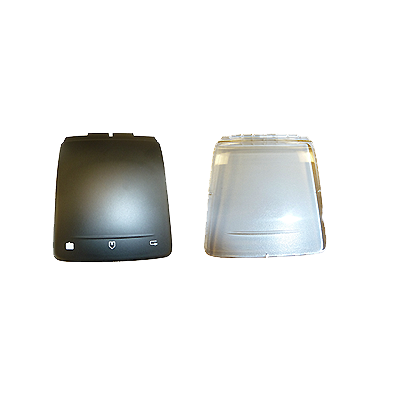

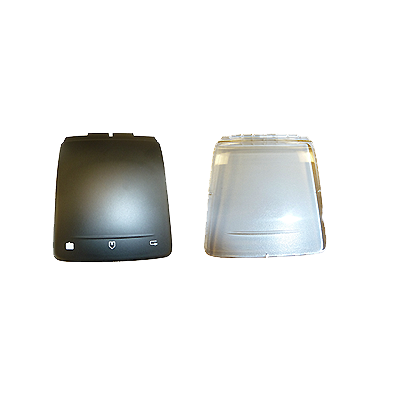

Attractive Lighting Solutions for High-Quality Parts

Front Lamp

Headlamp Cover

Lens

Light Guide

Light Reflector

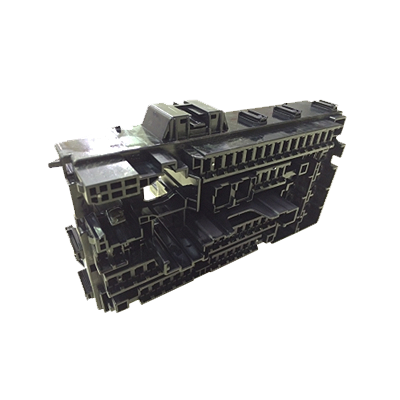

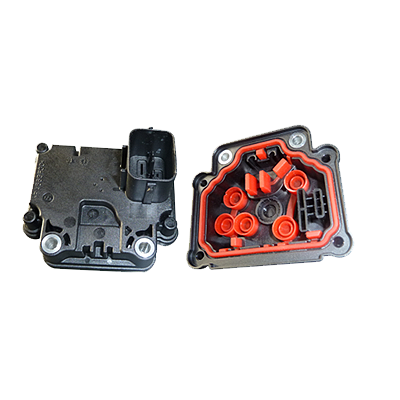

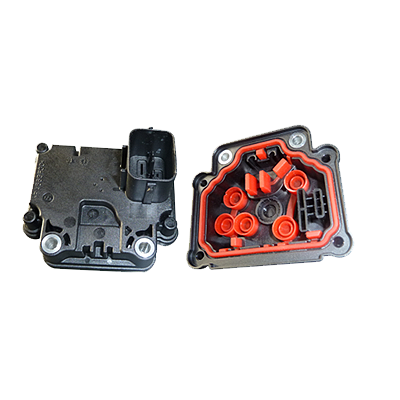

Auto Electrics

Electric vehicles, in particular, are equipped with a variety of sensors and control systems to monitor and control the operation of the vehicle. The manufacturing of housings and components for these sensor systems requires special engineering plastics that meet the requirements for resistance to environmental influences, temperature fluctuations and vibrations.

Cable Duct

Cable Guide

Connector Housing

Control Unit Housing

Brands We Work With

Drainage and Water Transport

Recycling and Waste

Industrial Logistics

Technical Parts

Electronics & Electrics

Industrial Electronics & Electrics

Consumer Electronics & Electrics

Power Tools

Domestic Appliances

Efficient Solutions for Industrial Applications

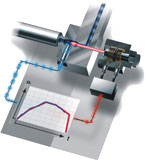

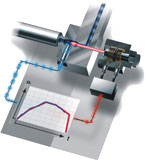

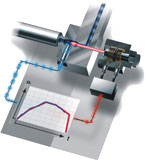

Synventive offers solutions and experience to the Industrial market that provide exceptional performance and quality. With solutions for color change, critical dimensions, balanced fill, and family part molding, we provide our customers with a wealth of experience to solve even their most challenging applications.

With a range of product solutions that include threaded nozzles, valve gates, mold flow analysis, and “Plug ‘n Play” systems, Synventive delivers performance that is backed by our service and support network and an industry-leading five-year warranty.

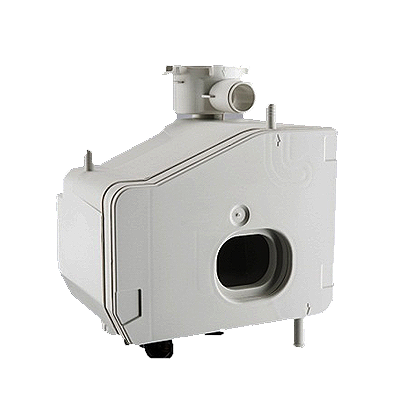

ELECTRONICS

Critical Solutions for Critical Applications

Synventive provides the Electronics market with high-quality systems that deliver performance for very demanding applications. Solutions for high pressure, critical dimensions, and balanced fill are delivered with a selection of products including threaded and support ring/sliding nozzles, valve gates, and mold flow analysis.

With all systems customized for the individual application, Synventive offers solutions that provide exceptional part quality with reliability that is backed by an industry-leading five-year warranty.

MEDICAL

High Precision Through High Performance

Synventive provides systems to the Medical market that are engineered for both performance and high quality. Our systems provide solutions for critical dimensions, balanced fill, high cosmetic surfaces, and color change while providing industry-leading quality that is backed by a global service and support network and a five-year warranty.

With innovations such as eGate® electric valve gates and threaded nozzles, Synventive provides clean systems that do not exhaust particulates into the molding environment and are leak-free by design.

PACKAGING

Simplify Your Solution

Synventive provides the packaging market with hot runner systems that meet the challenges these types of parts provide. Systems for high-pressure molding, balanced fill, color change, multi-material, and optimal cosmetics are all provided to this market.

Complete hot halves that are shipped pre-plumbed and pre-wired save mold makers and molders a substantial amount of time and help brand owners speed time to market, which is critical in this industry.

Bio-Resins & Sustainability

COMING SOON!

STAY TUNED FOR MORE ...

Bio & Recyclables

/Field%20Services/synventive-services-fieldservice-image-3.jpg?width=575&name=synventive-services-fieldservice-image-3.jpg)